Michael Brinker adn Quincy McGee | J.S. Held

Overview of Plumbing-Related Construction Defects

Plumbing-related construction defects can result in costly water damage claims. Recent innovations in plumbing materials and fittings have aided in more economical installation costs; however, workmanship issues and deviations from installation instructions for these materials have led to a rise in plumbing-related claims. Often these issues manifest months or years after testing and completion of the project.

This paper will discuss several common plumbing fitting installation deficiencies and detail proper installation practices. The following information may be of particular interest to plumbers, general contractors, property owners, insurance adjusters, and attorneys.

Evolution of Plumbing Materials and Fittings

For much of the 20th century, copper piping coupled with soldered joints composed the most common water plumbing material. Cutting, routing, and soldering copper piping is labor intensive and requires skill and experience. Such skills were obtained through hands-on apprenticeships and trade schools, and the technique was applicable for all copper connections. With the rise of plastic materials in the 1980s, alternative piping materials and connection methods began to supplant copper materials, with chlorinated polyvinyl chloride (CPVC) and polybutylene (PB) piping being the initial materials of choice. Today, residential and commercial water plumbing systems are primarily constructed of cross-linked polyethylene (PEX). Copper piping is still used in select applications, though copper press fittings are now more commonly used in place of soldering. While these newer materials can be assembled faster with less “skill,” there are now numerous connection components, methods, and assembly tools which can differ from project to project and manufacturer to manufacturer. Therefore, following manufacturer instructions for specific components and application is critical to ensure connections remain leak-free for the life of the material.

Common Plumbing Fitting Methods and Installation Issues

Compression fittings are a versatile method of joining and sealing two water-carrying components. They can be used to join two metal pipes, a metal and a plastic pipe, or two plastic pipes, and connect metal or plastic pipes to valving or fixtures. Compression fittings are uniquely manufactured for a specific application. Compression fittings rely on mechanical forces to compress a pliable material and form a watertight seal.

Preassembled Flexible Connectors

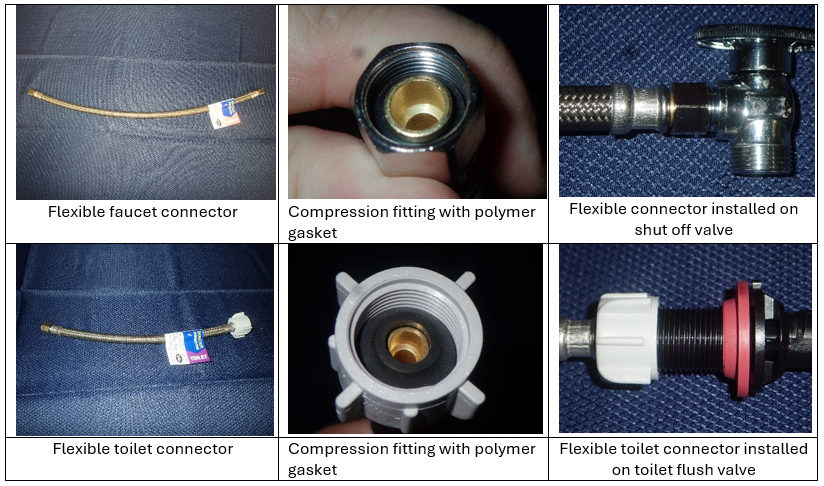

Preassembled flexible connectors are commonly used to connect faucets and toilets to a nearby shutoff valve. They are manufactured by crimping a fitting on each end of a flexible tube, typically ethylene propylene diene monomer (EPDM). The tubing is commonly sheathed with a high tensile strength material, such as nylon or stainless steel, to prevent bursting while under pressure. The fittings typically have captured nuts and polymer gaskets.

Each nut is threaded onto the respective supply valve and plumbing fixture, compressing the polymer gaskets to form a watertight seal. Preassembled flexible connectors are manufactured in varying lengths to fit a range of applications. Common installation errors include:

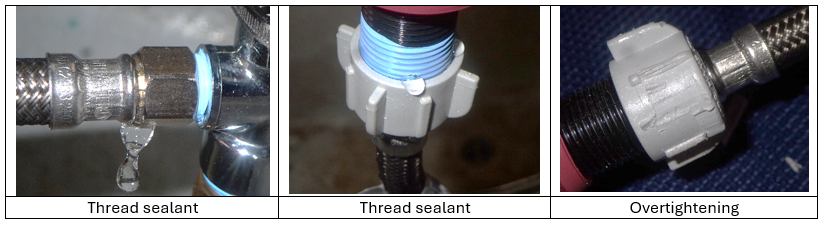

- Using thread sealants, which can prevent proper tightening of the fitting.

- Cross threading, preventing proper tightening of the fitting.

- Overtightening, resulting in gasket or fitting failure.

- Physical damage caused to the fitting when improperly tightened. Tightening instructions vary by manufacturer. Some fittings indicated hand-tightening only, while others may be tightened using tools but are commonly limited to a fraction of a turn past hand-tight.

- Under-tightening fittings, which will leak.

Copper Compression Connectors

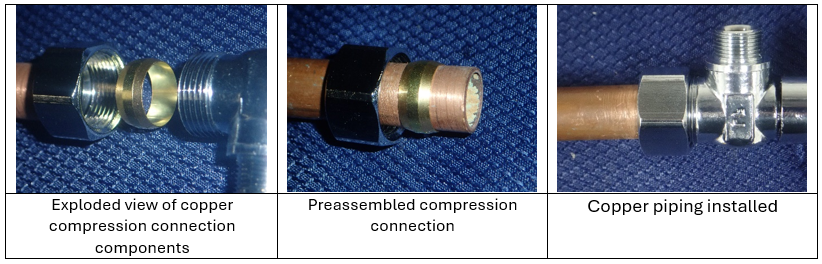

Although copper piping is less common in new construction, it is very common in older construction. Copper piping is long-lasting, durable, and corrosion resistant. It can be used to connect faucets, toilets, and other appliances to nearby shutoff valves, as well as for longer plumbing runs.

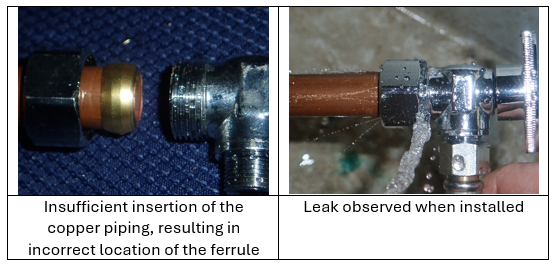

The nut is threaded onto the respective supply valve or plumbing fixture, compressing the brass ferrule around the copper piping and into the connector, forming a watertight seal. Tightening instructions vary by manufacturer but are commonly one-fourth to one-half turn past hand-tight. Common installation errors include:

- Issues such as those noted in Preassembled Flexible Faucet Connectors (above); under-tightening will also result in the tubing eventually slipping out of the fitting.

- Insufficient insertion of the pipe into the connection, and subsequently the incorrect location of the ferrule, which will result in the tubing slipping out of the fitting.

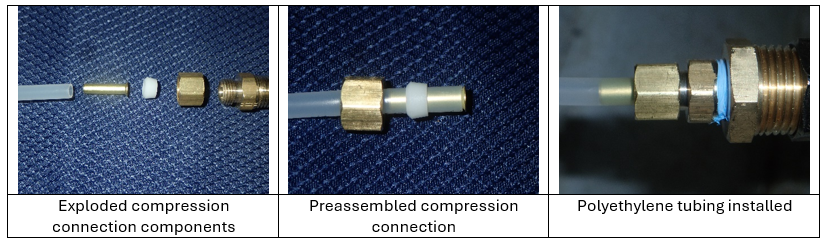

Polyethylene Tubing

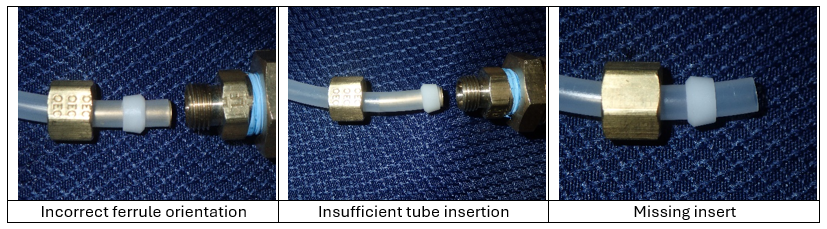

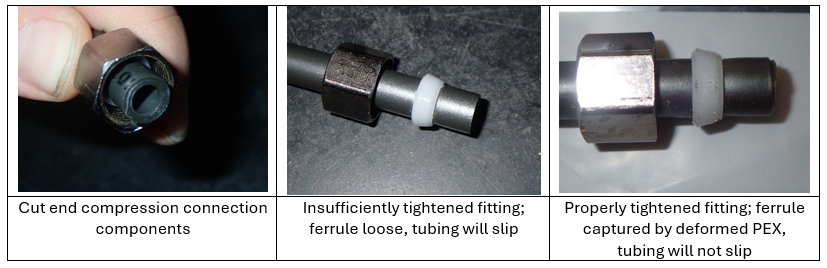

Polyethylene tubing less than ½-inch nominal diameter is commonly used for water dispensing applications, such as refrigerators, fountains, and ice makers. Compression fittings for this application consist of a ferrule, a rigid insert, and a compression nut with mating threads on a fitting. The components are sized for the specific tubing diameter. A plastic ferrule is typically recommended, as metallic ferrules can cut into the polyethylene tubing. The rigid insert, typically made of brass, is required to prevent tubing collapse. The ferrule inner surface compresses the tubing against the insert, which both secures the tubing and forms a seal. The ferrule outer surface compresses onto the fitting mating surface, forming a second seal.

The fitting manufacturer provides instructions for how to assemble and tighten fittings, typically a fraction of a turn past hand-tight. Common installation errors, which can be difficult to visually identify once the fitting has been assembled, include:

- Issues such as those noted in Preassembled Flexible Faucet Connectors (above). Under-tightening will also result in the tubing eventually slipping out of the fitting.

- Incorrectly orienting the ferrule. The tapered end of the ferrule should point toward the end of the tubing.

- Not fully inserting tubing into the fitting, which will result in the tubing slipping out of the fitting.

- Not installing the insert. The polyethylene tubing will deform and fail to seal.

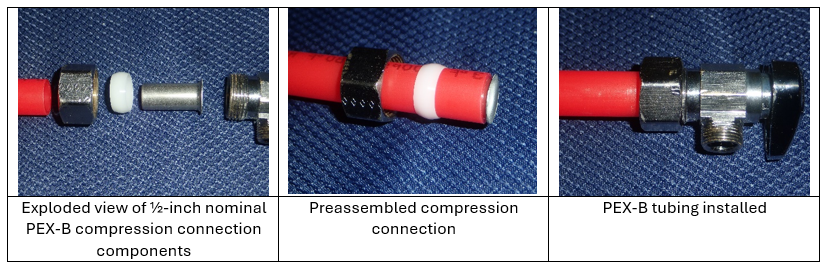

Cross-Linked Polyethylene (PEX)

While some manufacturers indicate that their compression fittings are suitable for PEX applications, using compression fittings for PEX connections is not common as there are other preferred coupling methods. Compression fittings that are suitable for PEX use may or may not require inserts, depending on the pipe diameter. A plastic ferrule is typically recommended, as metallic ferrules can cut into the PEX tubing. Further complicating the issue is that PEX has three classifications, A, B, and C, depending on the method used to manufacture the product. PEX-B is stiffer than PEX-A, while PEX-C stiffness can vary by manufacturer. All these factors can lead to variations in the tightening of the fitting.

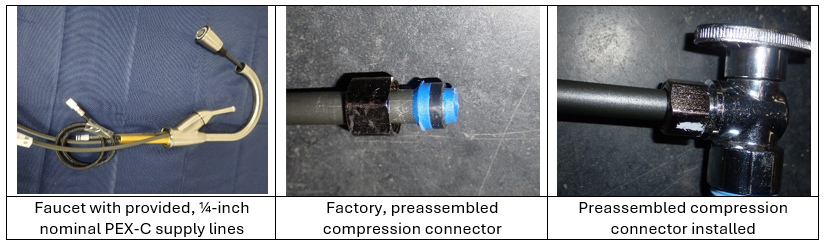

Faucets with Preassembled Connectors

To further speed up installations, some faucet manufacturers have begun producing faucets with preassembled connector lines, typically constructed of ¼-inch nominal PEX-C. The connectors are of sufficient length to fit a variety of installations. Because the materials differ from the typical preassembled flexible faucet connectors, manufacturers specify that the fitting be tightened significantly more than the typical flexible connector, typically two full turns past hand-tight. Some installers fail to review the manufacturer’s instructions for this unique application.

Further, some installers elect to cut the preassembled lines to a specific length to provide a cleaner fit for the installation. This requires assembly of a compression fitting, which can result in the installation errors previously noted. Failures have resulted when installers incorrectly perform the same tightening procedure as for polyethylene tubing, assuming both materials are the same plastic. However, PEX tubing is significantly stiffer than polyethylene tubing, and the fitting must be tightened according to the manufacturer’s instructions to provide sufficient compression.

PEX Crimp Ring and Expansion Fitting Installation Errors

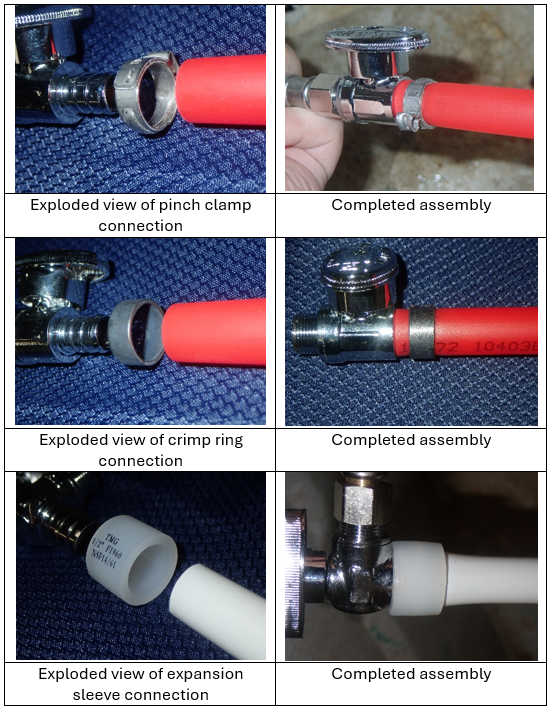

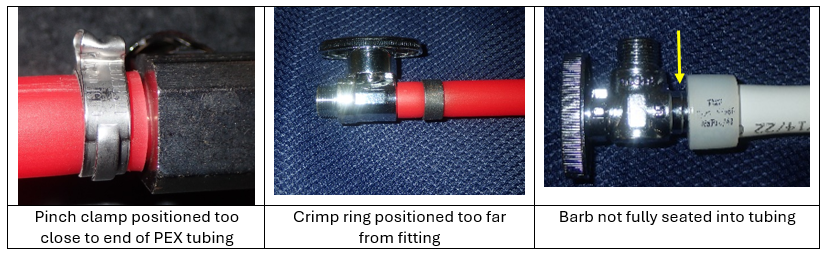

PEX is commonly connected by using barbed fittings inserted into the PEX tubing, with a metal pinch clamp, metal crimp ring, or PEX expansion sleeve compressing the piping around the barb. Both pinch clamps and crimp rings require specialized tools which need to be calibrated and maintained to ensure the metal is sufficiently deformed to apply the appropriate compression force. Expansion ring tools do not require formal calibration but do require routine maintenance. Further, selection of the correct expansion tool attachment, which is based on the tubing outer diameter, is critical to ensure the sleeve applies the appropriate compression force once the sleeve material relaxes.

The fitting can either leak or the tubing can detach from the fitting due to the following installation errors:

- Crimping is performed with an uncalibrated tool.

- The ring or sleeve is not centrally positioned over the barb and/or the barb is not fully seated in the PEX tubing. These issues result in poor engagement between the ring/sleeve, PEX tubing, and barb.

- Expansion sleeve is over-expanded and does not provide sufficient compression once the sleeve material relaxes.

Preserving Evidence in Water Loss Investigations

It is important to preserve the components and document an evidence chain of custody when investigating a water loss where faulty workmanship is suspected. To preserve any witness marks indicative of the initial installation and assembly, no attempts should be made to reconnect separated joints. The point of failure should be photographed from multiple angles. Any manufacturer labeling, printings, or stampings should be documented. Connected upstream and downstream piping and fixtures immediately adjacent to the point of interest should also be photographed. The water pressure at or near the point of interest should be documented, as well as the make, model, status and settings of any pressure producing or reducing devices. Documentation of materials surrounding the point of failure can aid in dating the failure.

If immediate removal of the failed component is necessary, marking should be applied and photographed prior to removal of components so that the orientation and direction of flow can be later identified. The failed joint should be collected in the as-found condition, which may necessitate removing unaffected components immediately upstream and downstream of the point of interest. Where applicable, exemplar fittings should be photographed, marked, and collected. Other contributing factors could include chemicals stored nearby, ultraviolet light impingement on components, deficient supports, or water quality issues, and therefore, additional points of interest may need to be documented, or samples may need to be collected.

How Consultants & Engineers Can Help

Compression, crimp, and expansion ring fittings use compressive forces to form a watertight circumferential seal. If these connections are not properly assembled, the connection may leak or separate, which can result in extensive water related damage to the building where the fitting was installed. It is critical for the installer to adhere to the manufacturer’s instructions and to recognize the potential installation issues. In the event a water damage loss occurs due to a failed fitting, it is important to document and preserve the evidence to ensure the best possible subrogation opportunity.

Consultants and engineers with experience in plumbing-related losses can be a great asset. It is important to enlist the right experts as early as possible when handling current or potential issues involving material failures or improper installations such as those discussed in this article.

When one of your cases is in need of a construction expert, estimates, insurance appraisal or umpire services in defect or insurance disputes – please call Advise & Consult, Inc. at 888.684.8305, or email experts@adviseandconsult.net.